Designed for performance, built for reliability — our Cook-Chill kettles deliver efficiency at every stage. Connect with us to learn more!

Cook & Chill Kettles & Mixers: Should You Chill in the Same Vessel or Use Separate Chilling?

Cook & Chill Kettles & Mixers: Should You Chill in the Same Vessel or Use Separate Chilling?

When it comes to cook & chill systems in food manufacturing, one of the biggest decisions is how and where to chill your product after cooking. At PerMix, we manufacture advanced cook & chill kettles and mixers designed to give you flexibility based on your production needs. But should you chill in the same vessel you cook in, chill in a separate tank, or package the product hot and chill it in a water bath?

Each method has its own advantages, disadvantages, and ideal use cases, and understanding the differences can significantly impact product quality, throughput, and sanitation. Here’s what you need to know:

1. Cook & Chill in the Same Vessel

Using a PerMix cook & chill mixer or kettle allows you to both heat and cool your product in one machine, thanks to integrated heating & cooling jackets.

✅ Advantages:

- One-step process saves time and reduces labor.

- No transfer required, minimizing product loss and contamination risks.

- Ideal for products like sauces, soups, and ready meals that require precise temperature control from cooking through chilling.

- Allows for automated CIP (Clean-in-Place) and better sanitation control.

- Reduces equipment footprint and simplifies workflow.

❌ Disadvantages:

- Can tie up the equipment longer, reducing batch turnover speed.

- May require high-capacity chillers to meet demanding cooling times.

- Not always ideal for high-volume production environments where faster throughput is a priority.

2. Chill in a Separate Vessel

This method involves cooking in one vessel (such as a PerMix steam-jacketed kettle) and then transferring the product to a separate chilling tank or mixer.

✅ Advantages:

- Increases throughput by allowing you to cook the next batch while the previous batch is chilling.

- Flexibility to optimize chilling separately, with larger chillers or different chilling media (glycol, ice water, etc.).

- Great for operations with multiple unit lines or continuous production.

❌ Disadvantages:

- Additional equipment costs for the chilling vessel and piping.

- Higher risk of contamination or product loss during transfer.

- Increased need for cleaning multiple vessels and transfer lines.

3. Package Hot and Chill in a Water Bath

A more traditional approach involves packaging the product hot into containers or bags, then chilling them in a cold water bath or tumble chiller.

✅ Advantages:

- Efficient for products that are immediately packaged, like soups, gravies, and sauces.

- Allows sealed, portion-controlled packaging before chilling.

- High throughput with batch tumbling systems that can handle large volumes.

❌ Disadvantages:

- Product must be at packaging-safe temperatures before sealing to ensure safety.

- Requires additional steps like sealing, handling, and bath immersion.

- Water baths must be carefully monitored and sanitized, which increases cleaning requirements.

So Which Cook & Chill Method is Right for You?

At PerMix, we help customers choose the best system based on:

- Product type (liquid, semi-solid, particulate)

- Batch size and frequency

- Sanitation requirements

- Available floor space

- Desired throughput

Many operations are choosing integrated cook & chill mixers with heating and cooling jackets because they offer greater control, less mess, and easier automation—especially when combined with load cells, PLC/HMI controls, and CIP systems.

However, packaged water bath chilling or separate vessel cooling may be better for high-volume lines where speed and continuous production are critical.

Why Choose PerMix for Cook & Chill Solutions?

PerMix leads the industry in affordable, high-performance cook & chill kettles and mixers, offering:

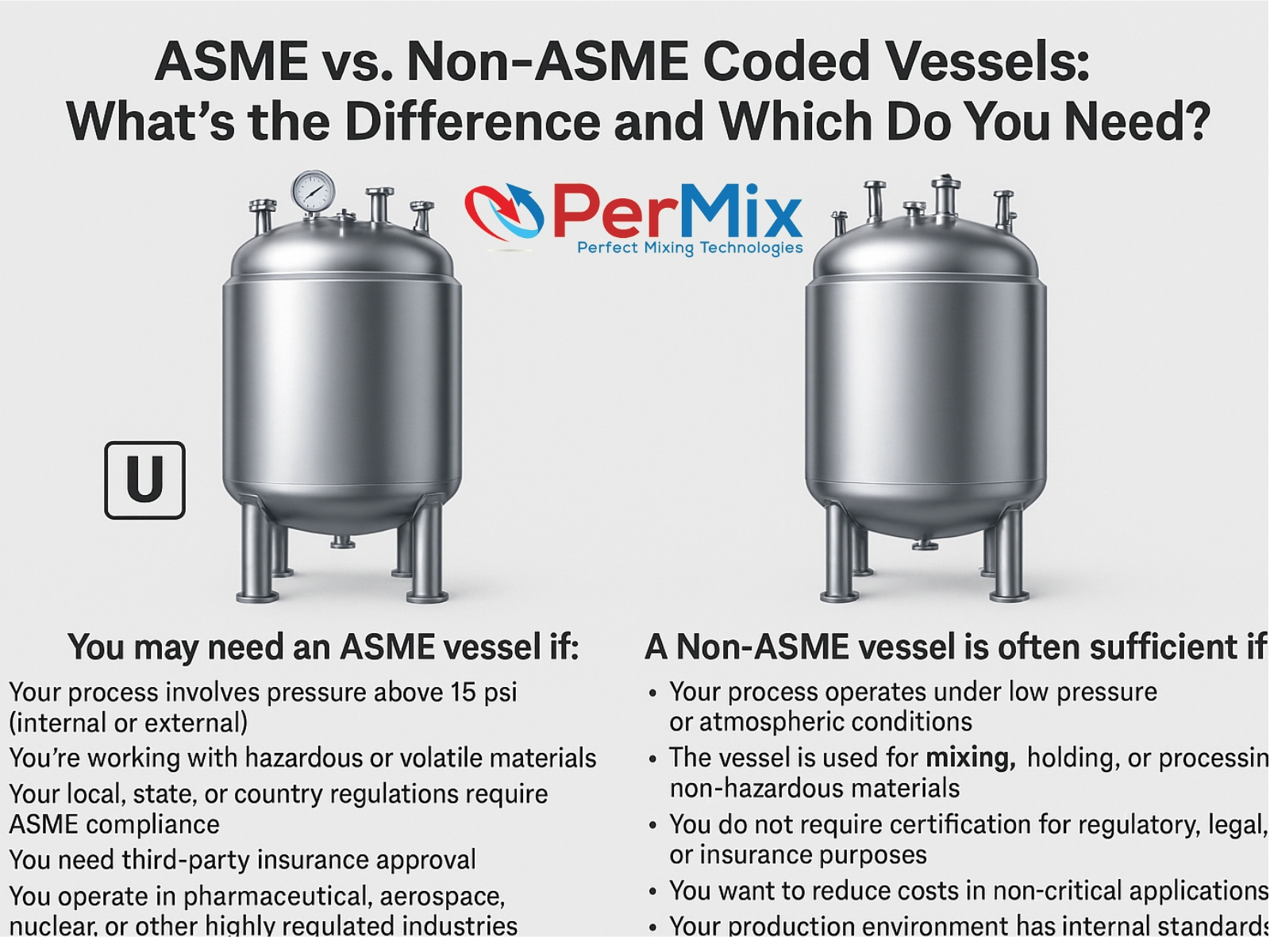

- ASME-certified jackets for pressure and vacuum cooking

- Advanced heating & cooling jackets

- Multiple agitation types for shear-sensitive or particulate-rich products

- Vacuum and gas purge options for enhanced product stability

- Customizable platforms with chilling tanks, CIP skids, and more

Need help choosing the right system?

Let PerMix’s engineering team help you design the ideal cook & chill system to meet your needs, improve product quality, and increase efficiency.